We spoke to Mike Mortimer and Mark Hoptroff, the directors of DG8, Icomera’s in-house design and engineering professional services business unit.

While introducing more new vehicles into service will contribute to the technological advancement of the transport industry over the next decade, it is the life-enhancing, life-extending upgrades of older vehicles that will have a greater, more immediate impact on supporting the transport industry’s overarching goals in a sustainable and cost-effective way.

Playing Catch-up

Ten years is not a long time in Rail, with limited valuable windows of opportunity to modernise rolling stock – realistically only one or two at most per vehicle – and equip them to meet challenges that are already very present.

Vehicles are always playing catch-up with new technologies, even before they have entered service for the first time. It starts with the long train procurement process, where manufacturers are building vehicles to specifications that were defined 4-5 years earlier and trying to incorporate technologies – particularly in the cases of those that are digital – that refresh every 5-7 years.

If the hardware required to support that technology is not installed during vehicle construction, it can face a five-year wait for the next opportunity, and the difficulties will only ever increase each time the window opens up again. Eventually there will come a point where the train design pre-dates even the conceptual stage of a new technology. This is something Icomera encountered when first installing its connectivity hardware on older rolling stock, trying to find the best way to route fibre optic cable through a train that was designed long before manufacturers understood that fibre optics was ever coming to the railways.

We will encounter this more frequently over the next decade as global events dictate the need for the faster adoption of a wider range of new technologies, from multiple vendors, across multiple vehicle classes. In the UK, for example, the average age of passenger rail rolling stock over the last 10 years has been between 17 and 21 years[1]. This is a huge number of vehicles that pre-date wider understanding of concepts like the Internet of Things, or emissions targets. But they will all be expected to play an equal role to their newer counterparts in terms of delivering a smarter, safer, and greener travel experience.

The Blueprints for Success

The projects that most successfully blend new technologies with older assets are those that keep the passenger’s engagement with their journey in focus: Design-led, from concept through to implementation, working across all tiers of the supply chain.

DG8 Design and Engineering was formed in 2008. In our early years, retrofitting vehicles with known third-party systems made up the largest percentage of our work. Now, with the increasing interest and availability of innovation funding (such as the UK government’s First of a Kind competition), retrofitting new and advancing technologies accounts for at least 60% of our active projects at any given time. This will only increase.

When (re)designing and delivering the onboard networks of devices and systems that will support the digital and energy transitions, the main challenges are (1) limited space and (2) the need for integration with current on-board systems. The rapid installation of safe and reliable modular systems across a wide variety of vehicle types requires innovative engineering designs and electrical engineering.

The three examples that follow offer early insights into the potential of what can be achieved in the near-term when transport authorities, operators and/or rolling stock owners engage partners with the required competency and capacity at the earliest stages of the project.

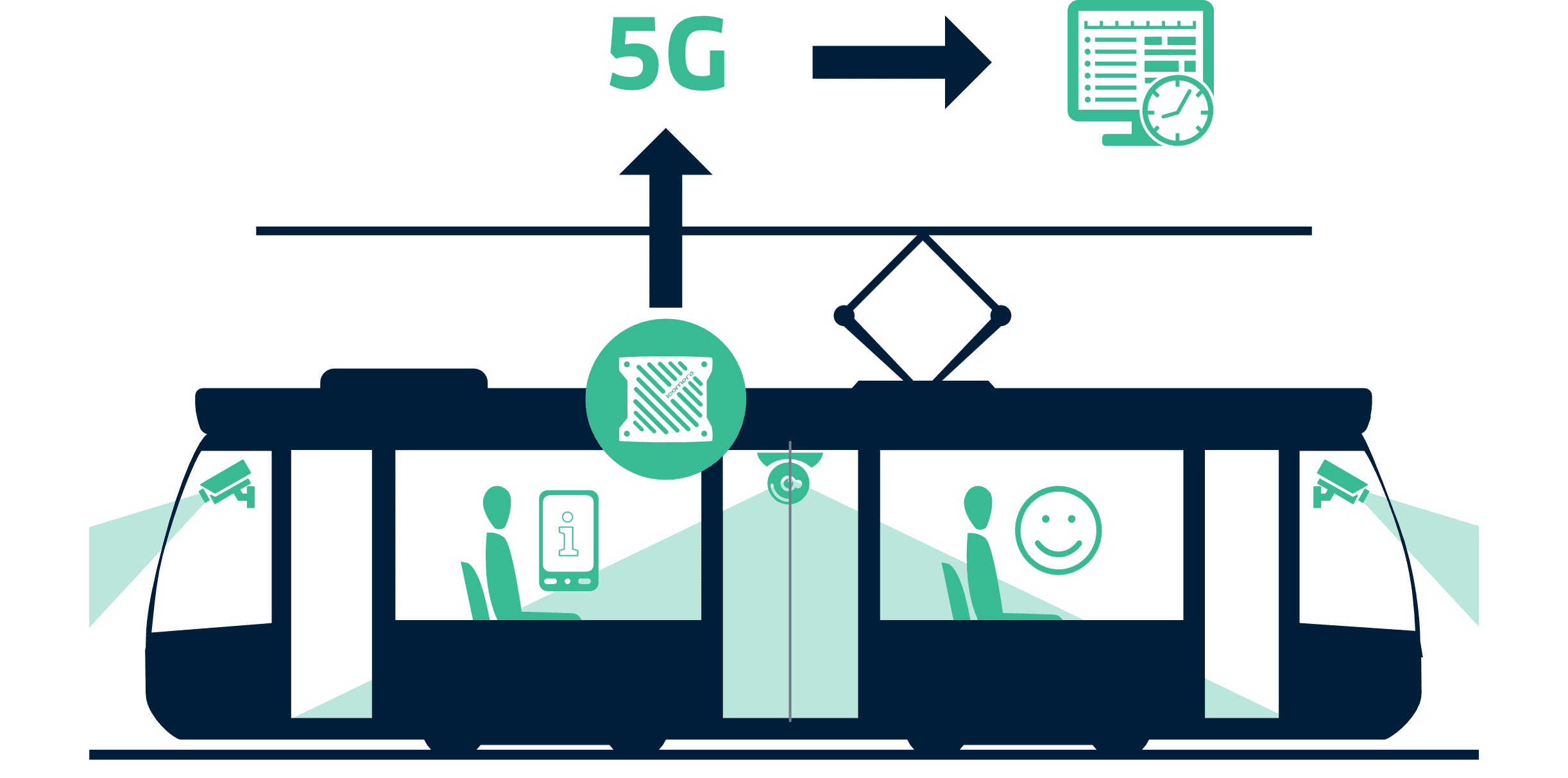

5G-Enabled Tram – West Midlands Metro

As part of the UK’s multi-million-pound West Midlands 5G (WM5G) programme, DG8 was tasked with adding Icomera’s 5G connectivity solution to a West Midlands Metro (WMM) tram – becoming the country’s first 5G enabled tram in the process.

The work began during the early months of the pandemic, and the project went on to become an award-winning demonstration of the technologies that will underpin the future of travel.

DG8 worked with the multiple project partners to package their systems and ensure the installation met industry standards. Connected applications offered Real Time Passenger Sentiment Analysis, Live Video Surveillance, and improved transport accessibility for blind and partially sighted people.

The limited space available on the tram required a compact design solution to neatly package the installation around existing onboard equipment. Installation was completed over the course of a day at West Midland Metro’s Wednesbury depot with the support of WMM’s depot team.

Infrastructure Monitoring – Network Rail

To improve safety and reliability, Network Rail, the owner and infrastructure manager of most of the British railway network, sought to increase the capacity of its dedicated fleet of Infrastructure Monitoring trains by converting two British Rail Class 153 passenger units into Visual Inspection units.

DG8 led the installation design and engineering, approvals (RIS-2700-RST), material supply and installation work.

The unit conversion was based around three complex digital solutions: 1) A track condition and geometry monitoring system, 2) a camera system recording images of the track and uploading the footage back to the Network Rail viewing platform, and 3) a positioning system that accurately tags the data from the other systems with the location on the network.

These systems require a hybrid power source with multi-mode controls to support recording while in service and post-processing while in sidings. The solution was to install an internal generator and supporting lithium batteries working in tandem. The systems were split into critical and non-critical, with critical systems receiving constant power, maintaining communication with the vehicle for data transfer on-demand.

The UK’s First Hydrogen-powered Train – HydroFLEX

The HydroFLEX project, led by rolling stock asset manager Porterbrook, involved the conversion of a 30+ year-old British Rail Class 319 train, fitted with hydrogen fuel cells, giving it the ability to run autonomously on hydrogen power on non-electrified routes. HydroFLEX is expected to play a key role in decarbonising the British railway network, by helping to replace diesel-only trains by 2040.

DG8 was responsible for the train’s mechanical installation design, including how best to integrate key components such as the hydrogen fuel tanks, fuel cell and battery module, and the interior design of the train’s ‘onboard boardroom’ conversion, giving passengers the chance to work with Icomera’s 5G Passenger Wi-Fi while travelling on the train.

In addition, DG8 supported the electrical installation design, working to ensure that it conformed to the railway industry’s specifications and best practices; performed structural calculations to verify that the items installed on HydroFLEX met structural compliance requirements; and provided support to validate the wider approvals process.

Working collaboratively with a number of skilled partners, we were proud to have been involved in this ambitious project to make the vision of the hydrogen powered train a reality in the UK, successfully creating the UK’s first hydrogen-rail supply chain in the process.

[1] https://dataportal.orr.gov.uk/media/1534/table-6313-average-age-of-rolling-stock-by-operator.ods

This article features in Icomera’s 48-page industry report “The Connected Journey Through Transport’s Transformative Decade”.

Supported by data and insights gathered from transport authorities, operators, and technology companies around the world, the report covers the trends and challenges shaping the future of passenger transport, and the role that connectivity will play in achieving the industry’s overarching goals…